The dental industry is transforming, thanks to cutting-edge advancements in 3D printing technology. Once considered an experimental tool, 3D printing has now become an integral part of modern dentistry, enhancing precision, efficiency, and patient outcomes. From custom dental prosthetics to orthodontic devices and even implants, this technology is reshaping how dental professionals and laboratories approach treatment planning and manufacturing.

The Rise of 3D Printing in Dentistry

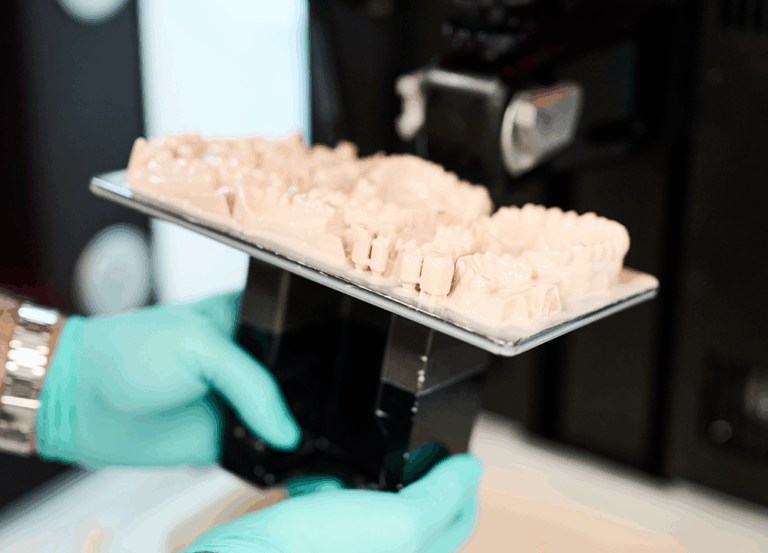

3D printing, also known as additive manufacturing, involves the layer-by-layer construction of an object from digital models. In dentistry, this technology enables the rapid and cost-effective production of customised dental devices, overcoming the limitations of traditional manufacturing techniques. Dental labs and clinics worldwide, including Andent Dental Laboratory, are increasingly adopting 3D printing as part of a comprehensive digital workflow to improve turnaround times and offer highly personalised solutions for patients.

Benefits of 3D Printing in Dentistry

1. Precision and Accuracy:

Traditional methods of crafting dental prosthetics involve multiple steps, which can introduce errors. With 3D printing, digital impressions create exact replicas of a patient’s oral anatomy, ensuring a perfect fit for crowns, bridges, dentures, and aligners. At Andent, our digital workflow ensures seamless integration from scan to design to print, helping us deliver high-precision restorations every time.

2. Speed and Efficiency:

The conventional production of dental prosthetics can take days or even weeks. With 3D printing, the turnaround time is significantly reduced. In our lab, we leverage advanced in-house 3D printing to accelerate production timelines without compromising quality.

3. Customization:

Every patient has a unique dental structure. 3D printing enables the creation of tailor-made dental solutions that fit seamlessly, improving patient comfort and treatment outcomes. Our team works closely with prescribing dentists to design and print individualized restorations that meet each patient’s specific needs.

4. Cost Reduction:

By minimizing material waste and streamlining the production process, 3D printing helps reduce the overall cost of dental restorations and appliances. Our digital workflow at Andent maximizes efficiency, helping to deliver cost-effective results while maintaining premium quality standards.

5. Enhanced Patient Experience:

Faster production times and improved accuracy mean fewer adjustments and quicker treatments, leading to higher patient satisfaction. Our investment in digital technologies ensures that patients benefit from faster delivery and superior prosthetic performance.

Applications of 3D Printing in Dental Prosthetics and Implants

1. Crowns, Bridges, and Dentures

Traditionally, creating crowns, bridges and dentures involves taking impressions, crafting wax models, and casting metal or ceramic materials. 3D printing eliminates these steps by directly printing ceramic or resin-based prosthetics, ensuring a precise fit and reducing patient wait times. At Andent, our 3D printers allow for the rapid production of both temporary and final restorations, improving workflow efficiency for clinicians and patients alike.

2. Removable Appliances

Removable appliances, such as 3D-printed nylon splints, have seen significant advancements thanks to digital workflows and additive manufacturing. We use high-performance 3D printing technology to produce nylon splints that are lightweight, durable, and precisely fitted to each patient’s anatomy. The digital design process ensures a consistent fit, while the nylon material provides excellent flexibility and strength for long-term wear.

In addition to splints, clear aligners, like those used in TrioClear® treatments, also benefit from 3D printing by using digitally printed models to fabricate a sequence of aligners. This approach allows for highly accurate and efficient tooth movement, with improved patient comfort and faster turnaround times.

3. Surgical Guides

For complex dental surgeries, precision is critical. 3D-printed surgical guides help dentists and oral surgeons plan procedures more effectively. These guides, made from biocompatible materials, ensure that incisions and implant placements are as accurate as possible, reducing complications and improving healing times and surgical outcomes. In our lab, we utilize 3D printing to manufacture custom surgical guides tailored to the specific needs of each case, helping to elevate clinical precision.

4. Temporary and Permanent Restorations

With 3D printing, dentists can provide patients with same-day temporary restorations, eliminating the need for multiple visits. Some advanced materials also allow for the printing of permanent restorations with durability comparable to traditionally manufactured ones. Andent’s digital production line enables the fast turnaround of both provisional and long-term solutions, backed by quality control at every stage.

The Future of 3D Printing in Dentistry

As technology continues to evolve, the possibilities for 3D printing in dentistry are expanding.

Researchers are exploring the use of bioprinting, which involves printing with living cells to create bio-engineered dental tissues. In the future, this could lead to the development of fully functional, regenerating teeth.

Additionally, advancements in material science are making 3D-printed dental prosthetics stronger, more durable, and more aesthetically pleasing. The integration of artificial intelligence with 3D printing may further optimize the design and customization of dental restorations, taking patient-specific treatment to new heights. At Andent, we’re committed to staying at the forefront of these innovations, continually enhancing our processes and product offerings.

Conclusion

3D printing is revolutionizing the field of dentistry, offering unparalleled precision, speed, and customization. This technology is transforming how dental professionals deliver care, whether for prosthetics, implants, or orthodontic devices. As research and innovation continue, we can expect even more groundbreaking applications to further improve patient outcomes and re-define the future of dental restoration and orthodontics.

By embracing 3D printing and a fully integrated digital workflow, labs like us are leading the way in delivering faster, more accurate, and cost-effective dental solutions. The future of dentistry is being printed, one layer at a time.

For more information about our digital workflow or 3D printing capabilities, please contact our local team via andent@andent.com or (03) 9650 6766.